Measuring RPM via spark plug lead

How fast is the mower engine going?

Measuring RPM

The RPM of an engine can be measured by counting the sparks of any of the spark plugs.

But why?

There are several reasons to do this.

Firstly you need to know when the engine stops. It might have run out of fuel, might have malfunctioned, or might have hit a thick patch of vegetation and stalled.

When a mower hits a clump of thick grass, it will slow down (obviously), and may even stall. There are two protections for this.

- If you are using swing blades then they will swing back, and simply stop cutting (or cut less).

- The governor will kick in, and turn up the throttle.

Some feedback about exactly how far the governor has opened the throttle would be handy too.

Another possibility is to replace the governor with a software-controlled throttle, which does the work of the governor. This adds complexity, but would provide excellent feedback in such situations. In principle it should be possible for a software controlled throttle to do better than a spring-based governor, but this would be an entire project in itself.

Components

| Arduino Nano | Cheap and expendable. | Various components | Various components for the circuit board. |

Construction

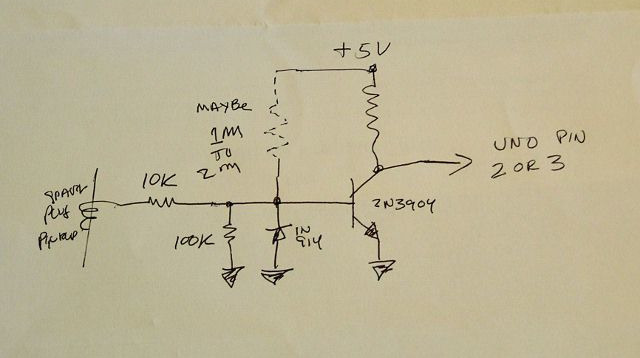

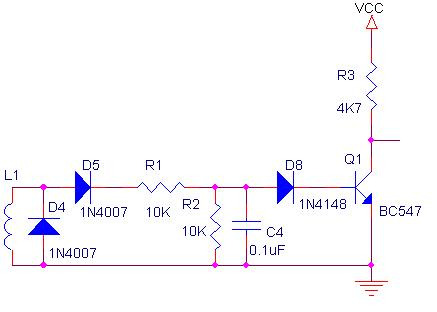

I liked the look of the first circuit because of simplicity (less soldering) and the safety diode.

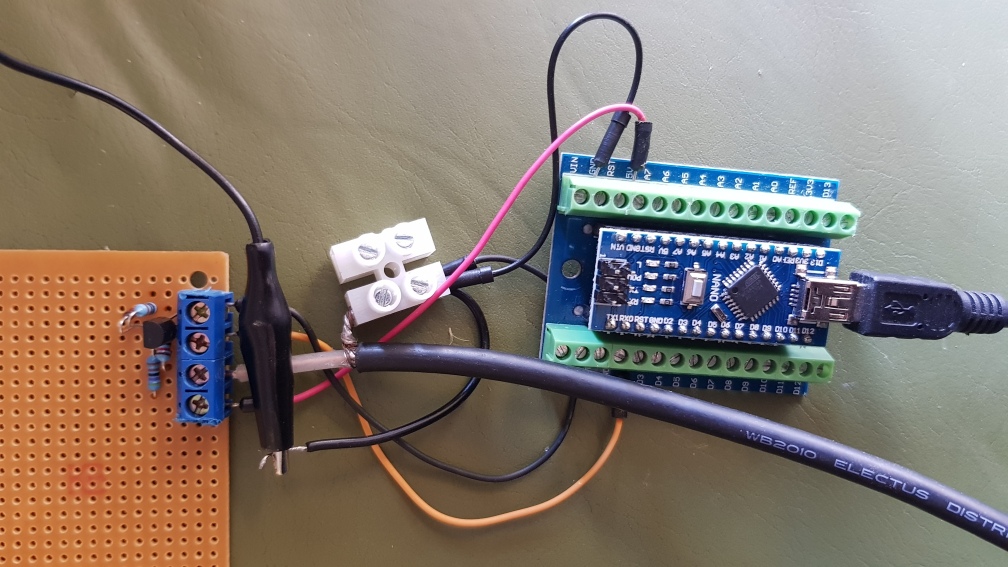

.. so I built that one (note I assumed the unlabelled resistor was a 4K7) , and here it is is in all its badly soldered glory (the black alligator clip is the ground for the oscilloscope). The probe to the spark-plug was picking up the fluros, and a bunch of (mains-AC) 50Hz other stuff, so used some co-axial cable. Much better.

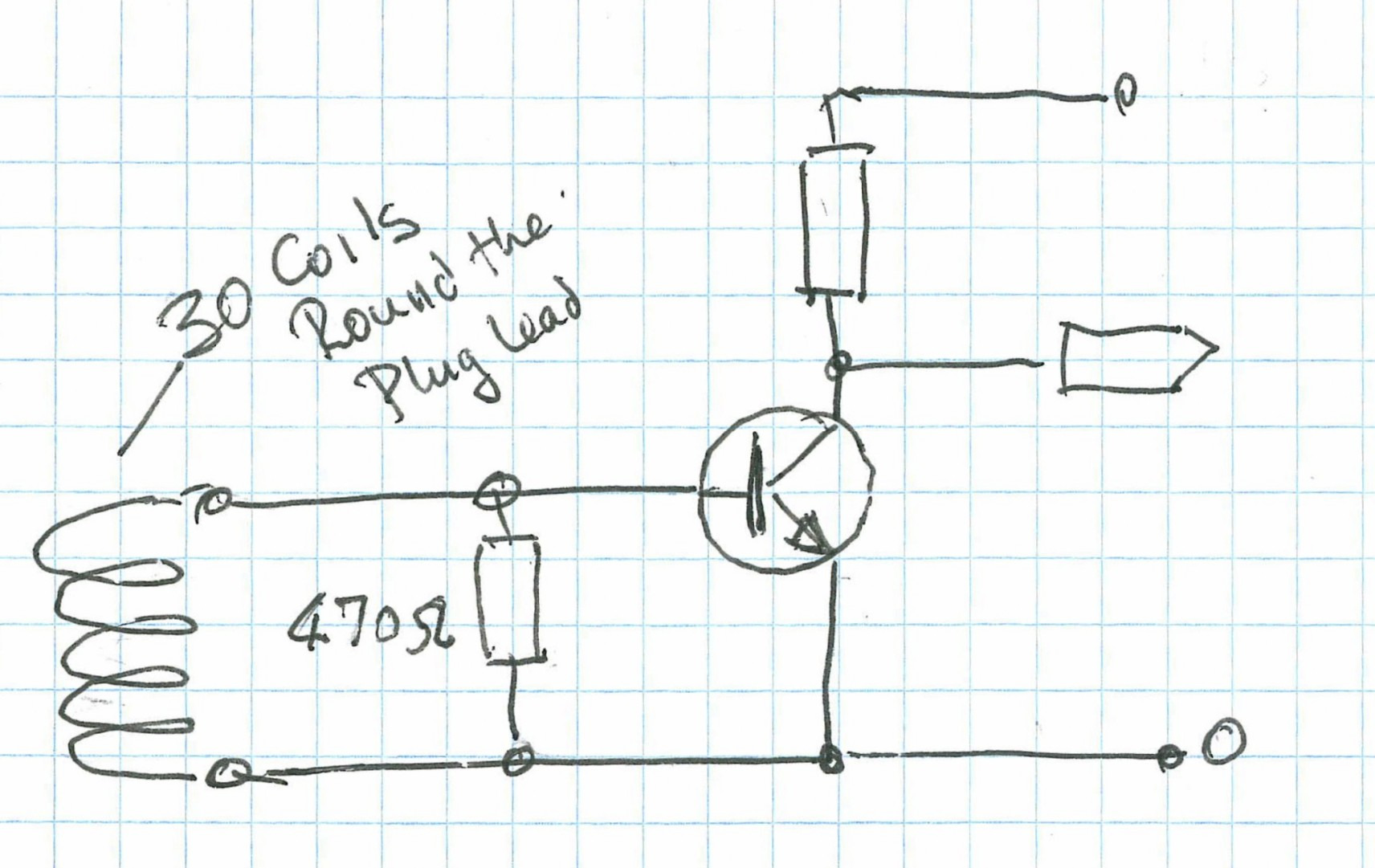

And the outer end was wrapped around the spark plug lead.

Ideally this should be more turns, and tighter, but this was a test ..

And the outer end was wrapped around the spark plug lead.

Ideally this should be more turns, and tighter, but this was a test ..Trigger warning ..

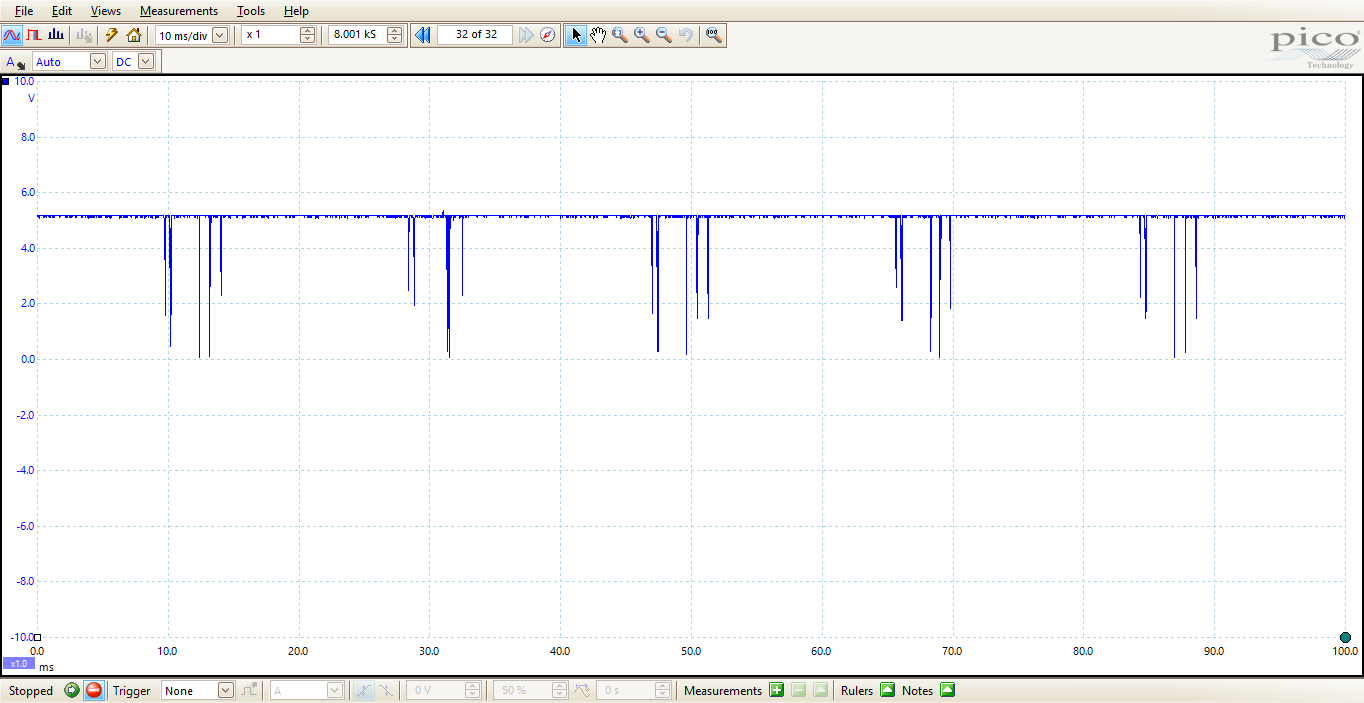

The output from the circuit to the Arduino interrupt pin was as snapshotted with the trusty Picoscope.

Well, that's a mess. Clearly the motor is spinning a little faster than 6000 RPM, but

Well, that's a mess. Clearly the motor is spinning a little faster than 6000 RPM, but

Great! Now all we need is ..

Result

I have a nasty burn on my hand from the mower exhaust. But I also have a working Arduino RPM counter.

Issues

It took a while to get around to completing this project, and it's still not integrated into the GizMow .. that's an issue.

Double or nuthin: just remember that some four-strokes activate the spark plug every revolution even though they only actually ignite fuel every second revolution (Google for wasted spark).

It may be necessary to double the the output to get actual RPM. Your mileage (or at least your RPM) may vary.

During testing the Nano crashed a number of times. Not sure is this a voltage dip problem or some other issue to do with the interrupts. This requires more investigation.

Conclusion

This is a viable method, but there are other approaches which might be worth trying. A Hall effect sensor on some spinning part or a photo sensor reacting to some silver tape?

Leave a comment

Think I might have solved your problem? Ninety-nine problems, but your robot ain't one? Say so ..